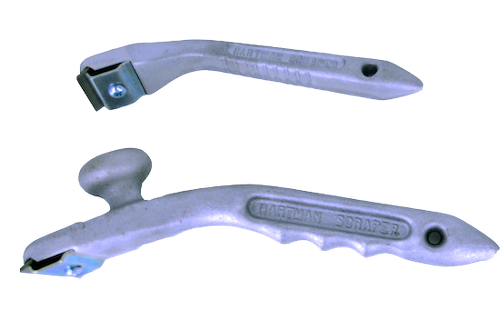

Aluminum Form Scrapers

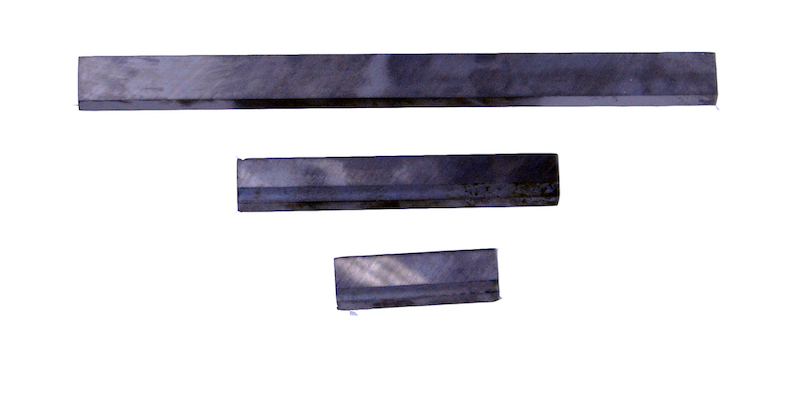

The size of the scraper indicates the width of the blade it uses.

- The 1-1/2” scraper can be used on any surface, but is particularly useful for side rails and end bars which are narrower.

- The 3” and 6” scrapers are for form faces.

- 6” scrapers allow a worker to stand on the form face and cover a large area and are great for hitting the high spots and getting the worst of the build up off.

Keep in mind that form faces are not perfectly flat, so the narrower the scraper, the finer cleaning you will get.

Handles that are built to last

Our incredibly durable scraper handles and heads are made of cast aluminum which allows for a light weight while maintaining enough girth and stability to get the job done right.

Our Blades

Carbide Blades

For over 25 years we have utilized carbide blades in our scrapers. Carbide is one of the hardest elements available and has the ability to stay sharp for extended uses. The C-2 carbide used by Hartman Scrapers has a Rockwell hardness of 90 – this is a harder carbide which will stay sharp the longest.

Tool Steel Blades

We have recently introduced heat treated D-2 tool steel blades as a less expensive option to our carbide blades. Our heat treated (hardened) tool steel has a Rockwell hardness of 60. While it will not stay sharp as long as the carbide, it is much less likely to chip, and is much easier to locate local re-sharpening service.

*When using carbide blades remember to be sure to only use it as a scraper. The hardness of carbide that helps it stay sharp also makes it brittle. If you get in a hurry and turn the handle in your fist and use it as a chipping hammer you will prematurely chip or crack the carbide, and greatly reduce the life of the blade, and the ability to re-sharpen it.